Plasterboard manufacturer Siniat has introduced a new EN-tested structural protectionsystem for steel that removes the need for traditional framing.

The system, which uses A1 non-combustible boards, provides 60 minutes’ fire protection.

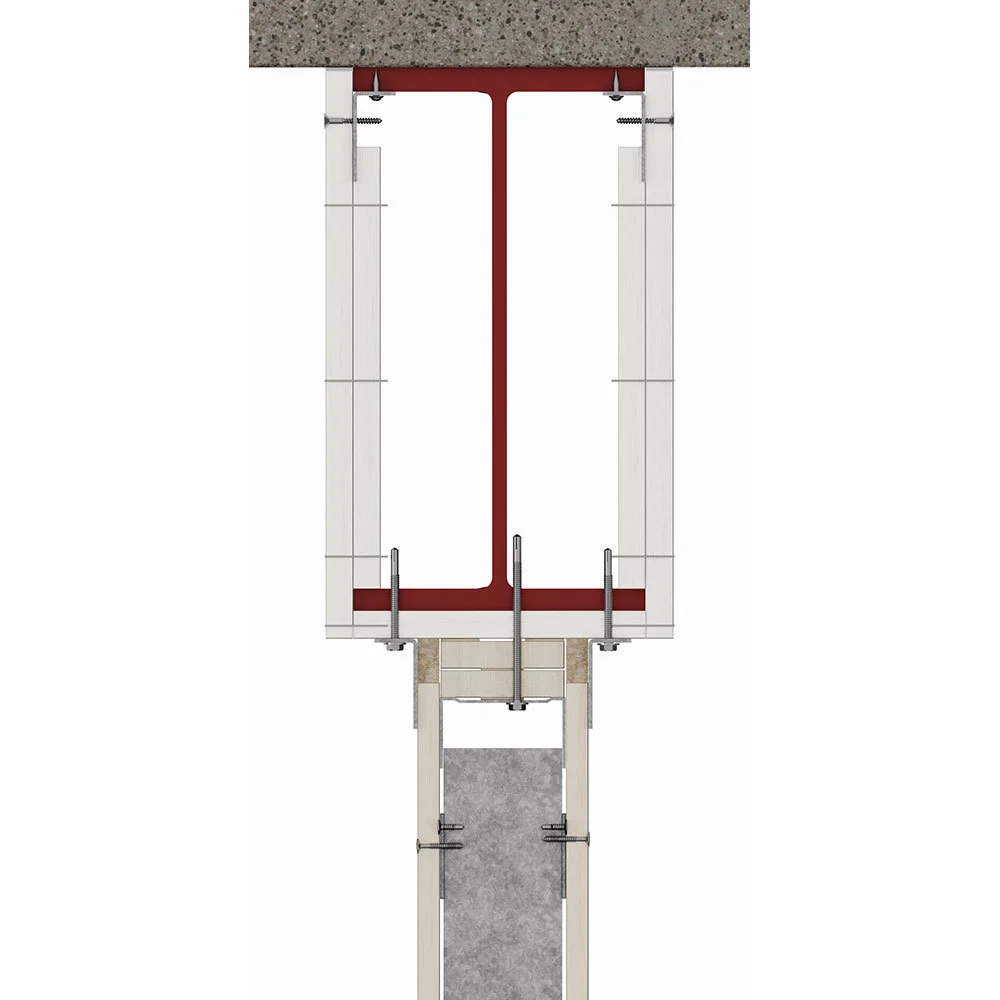

In addition, the board has been designed to ensure faster installation to support more economical ways of working and to save time spent on site. This sees a streamlined framing system used, featuring just one element.

Trials carried out by Siniat have indicated that the new system is almost a third faster to install than when using a traditional metal framing system.

The new system, Promatect®-XS, has been developed by Siniat’s sister brand Promat a specialist manufacturer of passive fire protection board systems.

The system is EN-tested and classified for steel fire protection, and also has evidence for maintaining compartmentation to prevent the spread of fire from one area to another. In-house testing has also been carried out covering interfacing of different Siniat systems, such as partition walls.

Head of specification for Siniat Steve Warriner said: “We are seeing an increased demand for data, and in response to market demand for evidence of interface performance we carried out bespoke internal testing to demonstrate this as no test standard currently exists.

“This system has been tested to the most up to date EN standards for its use in protecting steel structures, in addition to the in-house testing for interfacing between Siniat partitions and the encasement.

“Siniat offers market-leading levels of testing to demonstrate the technical capabilities of its board systems, and we have gone the extra mile to carry out bespoke testing for interfacing for this specialist fire protection system.

“With a strong focus on safer construction, we are seeing a constant demand for testing and data across a wide range of projects and uses. In carrying out EN testing, and classification, we aim to support the highest standards of building safety.”

“Siniat is committed to demonstrating high performance standards and we believe early adoption of EN testing, ahead of the 2029 implementation, supports best practice.

“The system also supports a need for faster installation – and the time and money that can be saved through that.”

In addition, the new system also supports sustainability objectives with the removal of the metal framing systems considerably cutting down the materials needed for the installation of plasterboard, in turn helping to reduce the embodied carbon in construction projects.

Find out more about Promatect-XS online.