Since the launch of the Government’s new housing targets, local authorities and councils are facing massive challenges, with many saying the targets simply cannot be achieved. Nik Teagle, Joint Managing Director of Frameclad, takes a pragmatic view on what can be done to help.

People need homes, and although a priority for the Government, what baffles me is that construction does not appear in the first draft of the industrial strategy, which is due to be finalised in spring 2025. The strategy currently concentrates on eight favoured industrial sectors, including clean energy, creative industries, defence, ‘advanced’ manufacturing, and digital technologies. Construction—whether of the advanced sort or otherwise—is not on the list.

I think we all agree that we need to get some momentum back into the residential market. But rather than set a target, we need an actual delivery plan. I see this as a massive opportunity for light steel frame specialists, and we are gearing up to meet this demand.

Testing and Accreditation

2025 has got off to a cracking start, as once again, for the seventh consecutive year, we have achieved BOPAS Accreditation. Thanks to our talented team, we passed the rigorous assessment without any non-compliances.

You might ask, why is this so important? Our light steel systems are being widely specified in the residential sector. BOPAS provides assurances to lenders, developers, contractors, housing associations, and homeowners that construction systems designed, manufactured, and installed by accredited MMC providers will conform to industry best practices in terms of durability and system integrity. Most importantly, BOPAS guarantees that our offsite-manufactured light steel systems will stand the test of time and exceed 60 years or two mortgage terms—which is incredibly important to us.

Building safety is now rightly at the top of the agenda, but the regulation of construction products has not received the same level of attention. The UK government extended the recognition of CE Marking for construction products indefinitely in September 2024. This was after the previous administration set a deadline to replace CE Marking by June 2025. The extension was necessary due to insufficient testing and certification capacity in the UK to handle the required volume of conformity assessments if CE recognition were to end.

Housing developers will be appointed to deliver social housing schemes at scale while meeting Building Safety Standards and sustainability objectives. However, with so many untested products on the market, achieving these goals will be challenging. At Frameclad, we made a conscious decision to invest significantly in fire testing, certification, and accreditation. We have a growing bank of test data, and when it comes to bespoke light steel solutions, we develop testing programs with our construction partners.

Why Choose Light Steel Frame?

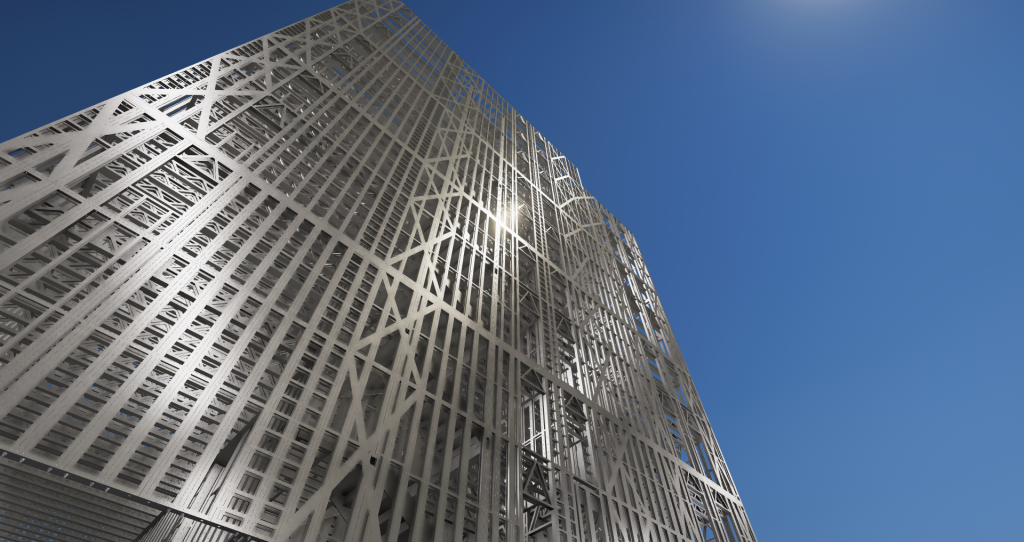

With its powerful combination of safety, strength, speed, and affordability, light steel frame is a cost-effective option for residential projects. As a key offsite construction method, it provides a fast and efficient way to build. Meeting Building Regulations and Building Safety Standards, our light steel systems hold the all-important BOPAS accreditation. Additionally, according to the Steel Construction Institute (SCI), they have a design life of more than 250 years in a warm frame environment.

Keeping tenants and homeowners safe, since the Building Safety Act came into force, light steel frame has become the preferred choice for housing projects. Robust and non-combustible, light steel frame creates highly airtight buildings, reducing energy costs for the lifetime of the homes.

Economic Gains of Light Steel Frame

With no shrinkage or settlement, light steel systems deliver residential buildings with longer lifespans without the need for remedial works and repairs. The stability of steel also leads to major reductions in long-term maintenance costs—a crucial factor for cash-strapped local authorities and social landlords.

Construction finance can be expensive, and project duration is critical to controlling costs. The speed of construction when using steel-framed panels or modules significantly shortens project schedules. Reducing the borrowing period can dramatically cut interest payments and total project costs.

Avoiding Overheating Issues

In addition to being strong and economical, light steel frames provide excellent thermal insulation properties. This ensures that heat transfer from external sources is minimized while internal temperatures remain stable, preventing overheating during summer months.

The exceptional acoustic performance of light steel frames makes them ideal for use in areas where noise pollution must be reduced or eliminated.

As we know, the pressure to provide high-quality homes at scale is immense. By adopting light steel frame systems and offsite manufacturing, this pressure can be substantially eased, giving local authorities and housing providers confidence that homes can be delivered cost-effectively and with energy efficiency at their core.

Frameclad

With an in-house team of 14 highly knowledgeable engineers and designers, Frameclad has the capability and technical know-how to tackle projects of any size.

If you are interested in how we can bring safety, speed, and a better return on investment to your residential project, check out Frameclad’s credentials and download our Residential Solutions brochure at: